The global maritime sector relies upon different parts of the supply chain from road, rail, and port infrastructure – whilst shipping customer assets – during this time the asset requires monitoring and real time reporting. With a global increase for fresh products and perishable cargo, the global container market has increased 3.5% in 2020 and is expected to grow 4% year on year to 2024. With the steady increase of containers in the supply chain there is a need for live monitoring, reporting and management of these assets creating a demand on finance, time, and effectiveness of maritime companies. While the container market increases, the industry still relies upon manual checks and processes with a fall out of high claims, lack of understanding and environmental impacts. Few companies are using this information intelligently to save on environmental impact, drive down costs and increase operational efficiency.

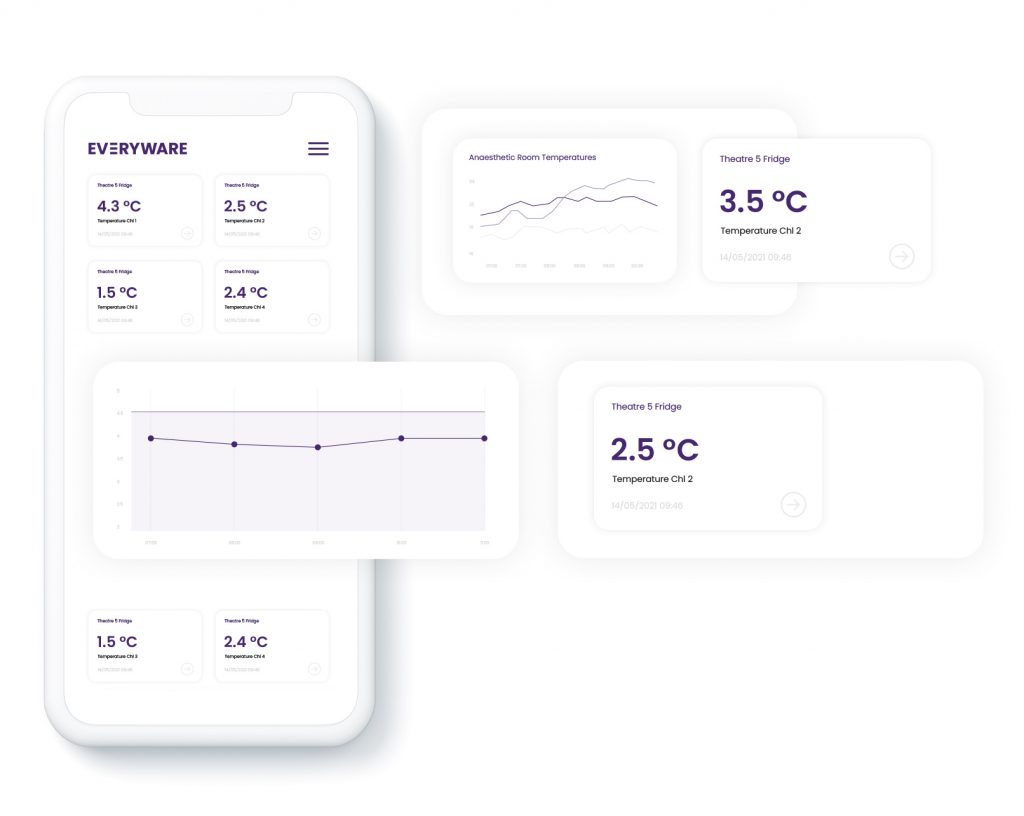

Our Innovation Services team focused on real time asset monitoring both on shore and at sea. Everyware has been working with the blue tech economy leaders and key maritime players in Southern Europe who are shipping large reefers and containers across the globe daily. The maritime industry, more than ever in a post-pandemic world, is embracing innovation and digital transformation solutions. Our IoT-enabled applications have been built in collaboration with product development experts in the maritime sector to provide ship owners with real-time information about their assets in transit. Data from bespoke sensors, developed by Everyware, feeds into the local port and ship management systems to drive rules and analytics that, for example, will highlight when containers may be at increased risk. Our sensors provide immediate alerts and feedback to ship operators, port agents and shipping agents when the container asset is at increased risk of perishing due to changes in conditions during transit. Our principle offering focuses on real time asset monitoring both on shore and at sea as well as GPS tracking of location.

Tuesday 8th June 2021

Automating the “cold-chain” supply-chain across maritime environments provides actionable intelligence for the ship management companies, port management and shipping agents. By having a real time monitoring solution for temperature-sensitive assets, we mitigate the increased risk of expensive cargo becoming perished, which can be incredibly costly, leading to undesirable financial and legal consequences.

Email: info@everyware.co.uk

Head Office

Chandos Business Centre, 87A Warwick Street, Leamington Spa, Warwickshire, CV32 4RJ, United Kingdom